Imagine a world where rust and decay spread unchecked across vital infrastructure, costing billions each year. That's the grim reality we're facing, but there's a hidden solution! This isn't just maintenance; it's an industrial revelation.

As global climates push materials to their limits, exploring advanced anti-corrosion coatings has never been more urgent. These coatings are quietly changing the game, promising to protect our bridges and buildings like never before. Are you curious yet?

Did you know that a specific coating type can extend the lifespan of infrastructure by a staggering 20 years? It's true, and yet many industries are still in the dark about these critical innovations. The coatings are not just an overlay; they're a technological force field! But that’s not even the wildest part…

Even in the harshest climates, where mere metal would crumble, these coatings stand their ground. What if I told you there's a coating that could heal itself when scratched? It sounds like science fiction, but it's the new frontier of defensive measures. Are you ready for an even bigger surprise?

The next innovation in industrial anti-corrosion coatings has experts talking, and what happens next shocked even the experts…

Understanding how anti-corrosion coatings work begins with unlocking their complex compositions. These coatings create an unbreakable bond with metal surfaces, forming a barrier that is impenetrable to moisture and corrosion catalysts. It’s like giving the infrastructure an invisible shield. But there’s one crucial detail about these bonds you probably don’t know yet…

The magic happens at the molecular level. Advanced coatings contain tiny particles that actively fight off attempts by elements to breach their defenses. They go beyond passive protection, becoming warriors in the battle against decay. But the science doesn't stop there; what you read next might change how you see coatings forever.

Some coatings are even designed to 'breathe', allowing the structure to naturally release trapped gases and moisture. This ensures longevity and can significantly reduce maintenance costs. Imagine cutting repair budgets by half! But there's still more to uncover about their potential savings.

The real revolution comes with self-healing properties. These futuristic coatings can repair minor scratches automatically, negating potential weak points. This technology is not only cost-effective but game-changing, altering the very standards of infrastructure protection. So, what’s the catch?

Every project manager knows the importance of protecting investments, but overlooking anti-corrosion can cost millions. Studies have repeatedly shown that infrastructures without proper coatings deteriorate twice as fast, leading to exponentially higher maintenance costs. It’s a financial blunder many learn the hard way.

Consider this: projects that skimp on coatings could accumulate ten times more in repair costs over a decade. These figures aren’t hypothetical—they come from real-world case studies where short-term savings led to long-term expenditures. Ignoring these coatings is like writing a blank check for damage control—but the stakes are even higher.

On top of immediate financial implications, the safety risks are astronomical. Without coating, structural integrity becomes compromised, posing dangers not just to the project, but also to human lives. Unexpected collapses and failures are not just seen in movies—they happen when protection is overlooked. Yet, many still underestimate the peril.

By investing early and wisely in modern coatings, businesses can protect assets and save many times their initial expenditure. Neglecting this crucial step has proven catastrophic; however, there’s an intriguing new development in this industry that might surprise you.

Cutting-edge materials are now at the forefront of anti-corrosion strategies, leveraging nanotechnology to create surfaces that resist even the most aggressive chemical environments. These advanced coatings don’t just sit on the surface; they become a part of it. It’s a seamless integration like never before.

The revolutionary addition of nanoparticles enables these coatings to provide superior protection with less material, reducing waste and improving efficiency. This represents a drastic shift in how we think about protective surfaces. But the innovation doesn’t stop at composition—something even more revolutionary is being developed.

Some coatings now use biomimicry, modeling after nature’s best defenses. Imagine a coating responding to its environment like living organisms do, adapting to threats and conditions. This bio-inspired design could set a new precedent for industrial resilience. Could this be the turn of the tide for durability?

The convergence of these technologies means future-proofing infrastructure against corrosion like never before. As we continue to explore these innovations, it's clear that the implications for industry standards are profound and far-reaching. But what makes this a truly ground-breaking development?

While anti-corrosion coatings primarily serve protection purposes, they've also ventured into the realms of aesthetics. Manufacturers now offer coatings in a range of vibrant colors without compromising durability. This allows for creative freedom while safeguarding structural integrity.

Moreover, these coatings contribute to environmental conservation by significantly reducing the need for replacement materials. Less frequent maintenance means fewer resources consumed and a smaller carbon footprint. It turns out these coatings do more ecological good than initially thought.

Create a sparkle, minimize waste—sounds appealing, right? What many don't realize is that innovative coatings even purify the air. Some specialized variants have the ability to break down pollutants, offering an added layer of environmental protection. But what truly separates these coatings from their predecessors?

The sustainability factor cannot be overstated. With the integration of greener manufacturing processes, coatings are evolving beyond their defensive roles to become key players in the sustainability movement. What does this mean for the future of industrial practices? You might be surprised.

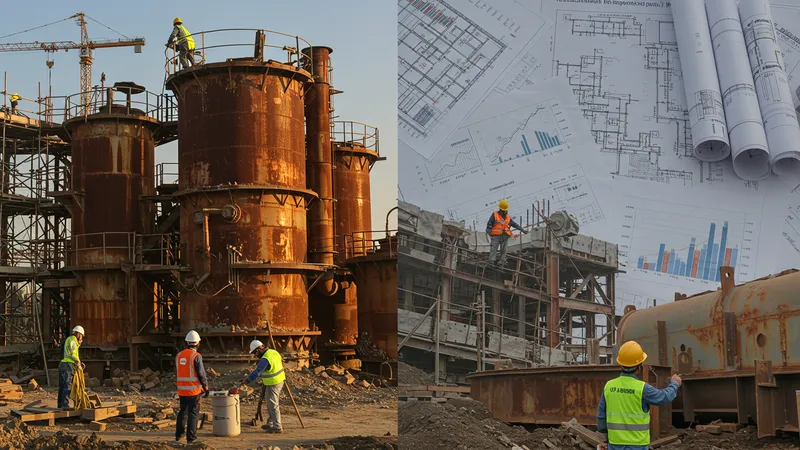

Across numerous sectors, the need for advanced anti-corrosion coatings has become critical. From oil and gas to transportation, where structures endure harsh conditions, coatings are indispensable assets. Their protective capabilities are undeniable.

Transportation infrastructure especially benefits from these innovations. With bridges and tunnels facing environmental pressures, coatings ensure longevity and safety, mitigating risks of failure. But that’s not where the influence ends.

The marine industry, facing constant exposure to saltwater, relies heavily on specialized coatings. These coatings must withstand extreme conditions while ensuring the longevity and performance of vessels and rigs. The question remains—how else do these coatings revolutionize this field?

As industries evolve, the need for robust protective solutions grows. The demand for coatings is reaching unprecedented highs, urging development beyond traditional systems. This innovation could spark a transformation across sectors, but what impact is waiting just around the corner?

In a rapidly changing world, the future of anti-corrosion coatings is incredibly dynamic. Developers are pouring resources into discovering the next big breakthrough. From nanotechnology integrations to smart coatings that react and adapt autonomously, the potential directions are endless.

Predictive maintenance systems, utilizing AI and IoT, are being developed to work alongside coatings, providing real-time data and alerts about structural conditions. Imagine an ecosystem where coatings communicate with technologies to enhance industrial health. How will this continue to evolve?

As the industry moves forward, the focus on developing solutions that not only protect but enhance functionality is growing. The emphasis is on creating coatings that are intelligent, adapting their properties in response to environmental shifts. But what does this mean for traditional coating methods?

Investing in research and development holds the key. As new challenges arise, establishing responsive and efficient systems ensures longevity both in performance and economy. This evolution not only promises better protection but signals a new era of industrial stewardship. So, what will the next breakthrough bring?

Determining the value of anti-corrosion coatings requires analyzing both upfront and long-term costs. Although initial investments can be significant, the savings accrued from reduced repairs and maintenance often justify the expense.

Consider a case where coatings decreased maintenance needs by over 30%. This reduction equates to substantial budget allocations for infrastructure improvements and expansions rather than repairs. But how do these coatings actually impact budget plans?

Comparing historical data, projects with substantial coating investments tend to outperform those without by a factor of longevity and reliability. The cost-effectiveness becomes more apparent when factoring in safety and economic stability, yet there’s still another layer to consider.

Despite the benefits, financial decision-makers must weigh variables unique to each situation. With technologies advancing, coatings become more accessible and affordable. The cost-benefit analysis consistently tilts toward future-oriented coating applications, proving their worth beyond expectations. But what hidden factors complicate this financial equation?

Not all coatings are created equal. Tailoring solutions to fit specific environmental challenges is crucial for maximizing efficiency and effectiveness. Coatings must be formulated for unique scenarios, from tropical climates to arid deserts.

Industries operating across diverse geographic areas face distinct challenges. Coatings engineered with consideration for local conditions outperform standard applications, supporting infrastructure resilience. Yet, what bespoke solutions await discovery?

For maritime environments, coatings engineered to resist salt corrosion can mean the difference between longevity and frequent repairs. Simultaneously, interior coatings in manufacturing facilities must withstand immense wear and tear, embodying a different kind of robustness. How do they adapt so seamlessly?

These tailored approaches offer powerful insights into optimizing infrastructural investments. By embracing a mindset of customization and precision, stakeholders can achieve unparalleled protection, driving future industrial success. But what about external threats we can't predict?

Setting a new standard in industrial longevity involves more than just applying a coat of paint. It's about precision and understanding the specific needs of each piece of infrastructure. This approach leads to exceptional results in durability and performance.

Advances in application technology, including robotic sprays and detailed inspections, mean that coatings are applied with unprecedented accuracy. This evolution in process efficiency minimizes material waste and maximizes coverage. What technological breakthroughs are elevating this standard even more?

Precision doesn't end at application. Continuous monitoring systems track performance and degradation, enabling proactive maintenance strategies to extend asset life. These systems transform reactive maintenance into strategic foresight—how else could this technological advantage be applied?

With innovations like these redefining the playing field, industries must adjust their strategies to remain competitive. Adopting precision grading means not just surviving, but thriving among competitors. The role of these coatings is continually transforming, bringing us to new heights. How does this redefine the entire infrastructure landscape?

The scope and implications of industrial anti-corrosion coatings are broader than just steel and rust. As the industry continues to evolve, these coatings are not just about protection—they represent an investment in the future, reshaping the landscape of possibilities. Integrating the latest technologies, industries can future-proof their assets, safeguarding both economic and environmental investments.

The call to action is clear: to explore and invest in these revolutionary coatings, ensuring infrastructure that withstands the test of time. Share this knowledge, bookmark these insights, and let’s spearhead a future where infrastructure is synonymous with innovation and sustainability.