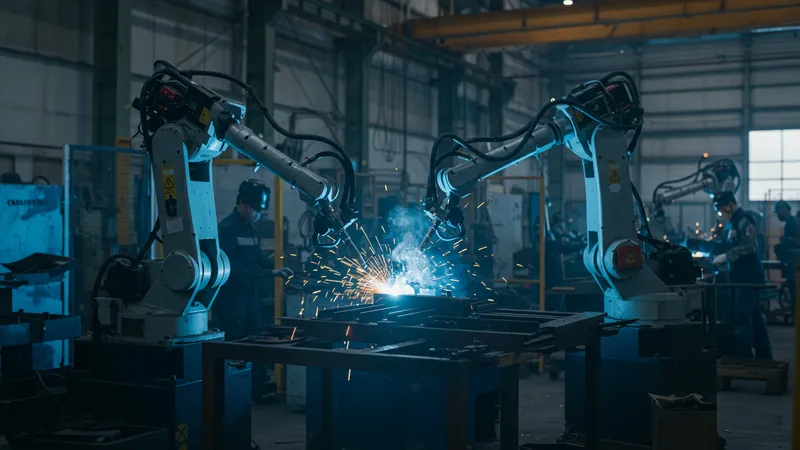

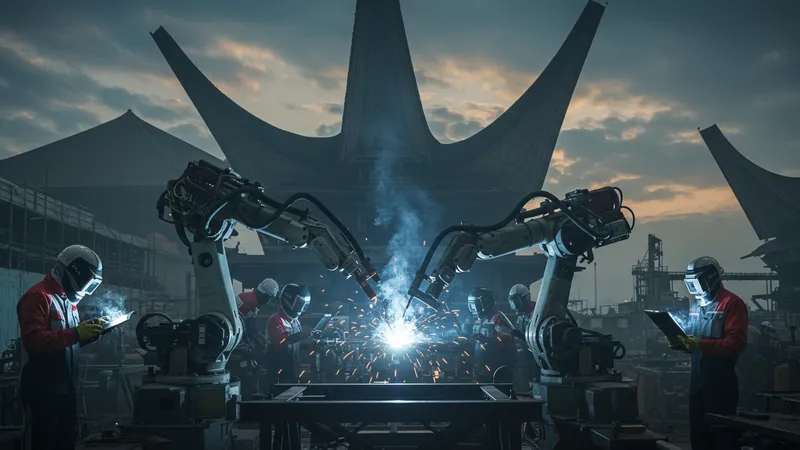

Imagine a world where tiny welding robots zip around factories more efficiently than any human could—Welcome to the dawn of revolutionary welding automation in Indonesia. It's a game changer no one saw coming.

This isn’t just tech for tech’s sake; it's the new backbone of Indonesian manufacturing, making waves right when global demand for efficiency hits its peak. Right now, understanding its impact is crucial for industry players.

The adoption of welding automation in Indonesia defies expectations. Rather than sidelining human workers, these smart machines are enhancing craftsmanship and safety protocols. Manual laborers are now trained operators, raising the skill ceiling. But that’s not even the wildest part…

With the national government providing subsidies, factory automation sees rapid growth, catapulting the country into a global manufacturing leader. Amazingly, this also cuts down production time by half. Yet, what’s happening in smaller industrial towns might shock you even more…

The integration of automation isn’t just about keeping up with the latest trend. It transforms economics, workforce, and even the socio-political fabric of a nation. What happens next shocked even the experts…

With welding robots flooding factories, one might assume job losses in Indonesia, but the opposite is happening. The demand for skilled operators who can program and maintain these machines has skyrocketed. Training programs are emerging across the nation, bridging the gap between technology and labor.

Interestingly, these new operators aren't replacing welders; they're often the same people, upskilled to handle more complex, rewarding tasks. Education centers are partnering with manufacturers to ensure workers adapt. But there's one more twist…

Those who once feared job redundancy discover a new career path that offers better pay and safer working conditions. It's a shift that aligns perfectly with global trends, where technology augments human ability rather than replaces it. This has been surprising even the staunchest critics!

While urban centers lead the way, rural areas are not left behind. Smaller workshops and factories are integrating automation practices, revitalizing local economies and providing stability for communities. What you read next might change how you see this forever.

In today’s competitive market, Indonesian factories must boost productivity without sky-high costs. Welding automation achieves this seemingly impossible feat. Efficiency levels surge with robots performing mundane tasks tirelessly, allowing human workers to focus on intricate processes.

However, the real surprise isn't just in numbers; it's how these machines allow factories to meet exact production standards consistently—impossible with manual labor alone. This level of perfection surprises clients worldwide, raising Indonesia's manufacturing reputation.

The seamless integration of technology into production cycles leads to massive decreases in waste. Less scrap metal equals less overhead and reduced environmental impact, making the industry greener. But there's an even more enchanting outcome…

As machinery takes over, the emphasis on precision engineering inspires a renaissance in craftsmanship. Human creativity, combined with robotic precision, crafts products previously unimaginable. What comes next could rewrite the industry’s future.

The Indonesian government plays a pivotal role in this automation trend. With tax incentives and subsidies, factories are motivated to invest in advanced welding robots, accelerating the transition. This foresight guarantees competitive edge in global markets.

What makes this initiative remarkable is how it supports not just big firms but also SMEs (Small and Medium Enterprises), evening the playing field. These initiatives also stimulate foreign investment, turning Indonesia into a hub for technological expansion.

The underlying goal is not just economic growth but also sustainable development. By ensuring that technology works hand-in-hand with human capital, the nation forges a path toward long-term progress. But guess what? There’s more to this strategic plan…

In a move that surprised economic analysts, Indonesia uses its newfound manufacturing clout to influence international trade agreements. The strategic positioning strengthens political ties, showcasing their role as a forward-thinking leader in the global landscape. The implications are profound.

While larger factories lead Indonesia’s automation narrative, smaller facilities are not far behind. These compact industrial units embrace innovation by adopting modular welding robots that fit limited space yet deliver impressive throughput.

The adaptability of these systems is astonishing. Robots recalibrate quickly for different tasks, making production lines versatile and efficient. It's a game changer for smaller players, broadening their capabilities without massive investment.

Small factory owners notice significant improvements in workplace safety and employee satisfaction. With robots handling hazardous tasks, human workers are shielded from risks, reducing accidents and downtime significantly. But that's not all…

These successes spread across various sectors, from automotive to electronics, showing that innovation isn’t exclusive to giants. Small factories’ ability to adapt to automation sets a new standard, proving strength lies in agility as much as in scale.

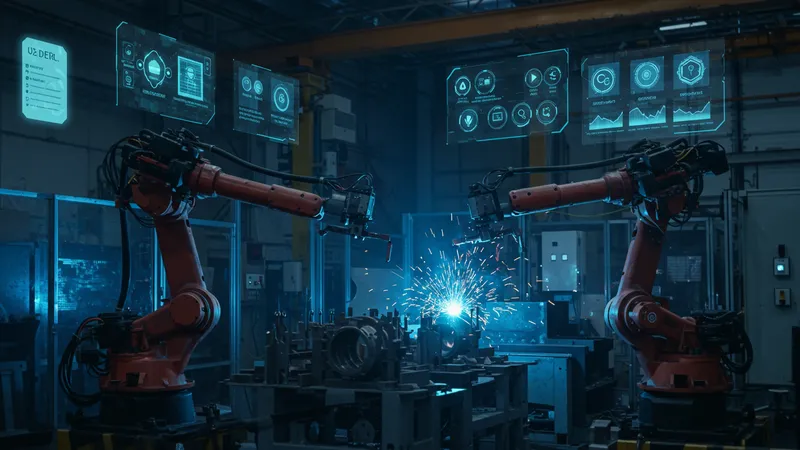

Enter the era of collaborative robots, or cobots—designed to work alongside humans rather than replace them. These machines extend capabilities without creating barriers, fostering teamwork between man and machine.

Indonesian manufacturers initially saw cobots as a novelty. However, their rapid, tangible benefits overturn skepticism. Cobots handle repetitive tasks, enabling human workers to fine-tune their skills and focus on creative aspects of production.

Their integration turns factories into dynamic ecosystems where efficiency meets innovation. Workers quickly learn to appreciate the value cobots add, resulting in enhanced morale and productivity. But what comes next is truly transformational…

These cobots can be programmed for a wide range of tasks, boosting operational flexibility. The potential for custom adaptation allows diverse industries to harness their power, pushing traditional manufacturing boundaries further than expected.

Welding automation in Indonesia affects more than just in-house production; it reshapes global shipping dynamics. With enhanced efficiency, Indonesian goods reach international markets faster, reducing delivery times and increasing customer satisfaction.

The consistency, speed, and reliability of automated welding contribute to Indonesia's appeal as a preferred export partner. This logistical advantage becomes a cornerstone in global supply chains, offering partners unparalleled value and dependability.

However, the broader implications of this shift are what intrigue economists. Automation isn't just a tool for growth but a catalyst for rewriting international trade norms. Collaborations with logistics companies streamline operations worldwide.

As costs dwindle and everything speeds up, Indonesian-made goods become more competitive. This rise in efficiency redefines market dynamics, inviting us to reconsider what’s possible in the realm of international commerce.

Welding automation's environmental impact surprises even seasoned experts. As robots optimize metal usage and mechanical processes, waste reduction becomes significant, aligning industrial practices with sustainability goals.

Factories consume less energy and raw materials, leading to a considerable drop in their carbon footprint. This shift resonates across industries, helping them meet stringent environmental regulations effortlessly.

The ripple effect on communities is profound. Factories become more responsible neighbors, integrating green practices into their core operations and winning public trust in the process. But that's not all—this new standard spreads quickly…

This transformation isn’t limited to urban centers. Rural factories also embrace these eco-friendly practices, witnessing palpable environmental improvements. What unfolds next may very well represent the future of sustainable industry.

Despite technological progress, cultural resistance remains a hurdle. Traditional views on manual labor being replaced by machines persist, though gradually diminishing as positive results emerge.

Surprisingly, educational campaigns showcasing technology’s benefits play a critical role. These initiatives illustrate that automation enhances rather than erases traditional work values, bridging connections with culturally rooted practices.

When communities see improvements in job safety and economic stability, skepticism melts away, replaced by cautious optimism. The cultural shift towards embracing technology accelerates diversification and growth.

This merging of old and new creates a uniquely Indonesian approach to modernization—one that respects heritage while embracing innovation. The journey is just beginning, setting a precedent for other developing nations.

Contrary to initial fears, robot integration into factories boosts rather than bleeds financial health for small and medium enterprises. SMEs leverage automation to standardize quality, qualifying them for larger contracts previously out of reach.

By minimizing defects and maximizing efficiency, products from these establishments compete globally, inviting increased revenue streams. Foreign investments funnel directly into areas previously overlooked.

The industry transformation is rapid, with SMEs adapting to technological demands at an astonishing pace. Community prosperity mirrors this shift, providing new employment opportunities in education and technology sectors.

Businesses anticipate potential risks and challenges, yet the overwhelmingly positive economic outcomes forecast an optimistic future. Watching closely, economists gauge how sustainable this growth might be in the long-term market landscape.

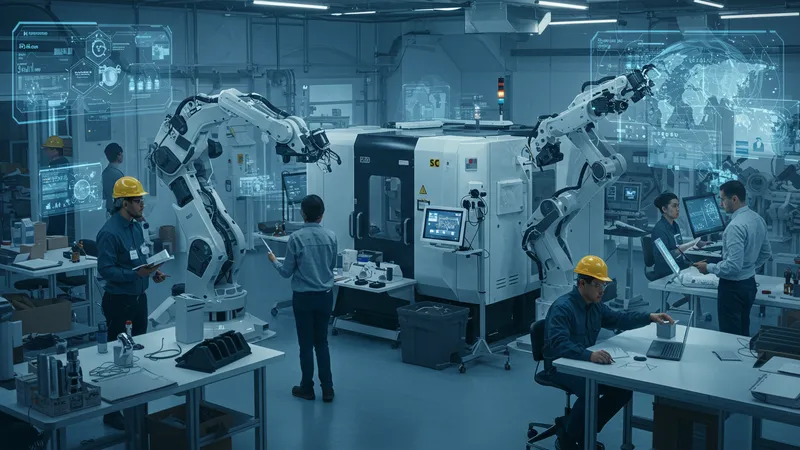

Labor dynamics face a seismic shift with the introduction of automation. Though change is traditionally feared, data shows a remarkable trend towards job transformation rather than elimination.

Workers once tasked with repetitive tasks now spearhead innovation, enlightening their potential to navigate complexities unknown before robotic collaboration. Upskill and reskill programs proliferate, aided by government and industry partnerships.

This nurturing environment sees individuals flourish, assuming broader responsibilities and acquiring specialized knowledge. The paradigm shift breeds resilience and adaptability—qualities crucial for tomorrow's workforce.

Industries outside manufacturing take note, reevaluating employment structures to accommodate this tech-oriented future. The stage is set for widespread implications that transcend national borders, influencing global labor policies meaningfully.

The rapid integration of smart technologies raises inevitable data security concerns. Factories store massive amounts of sensitive information—data breaches could prove catastrophic.

Solutions emerge through enhanced cybersecurity protocols. Manufacturers collaborate with tech firms to establish robust defenses, prioritizing transparency and consumer trust.

As cyber threats grow in sophistication, so does the technology countering them. The race to secure industrial data is relentless, demanding ongoing vigilance from all stakeholders.

With robust systems in place, industries foster secure environments that don’t just protect assets, but also boost partner confidence. Future cybersecurity innovations remain an area ripe with potential exploration.

Indonesia’s welding automation success becomes a blueprint for emerging economies worldwide. By marrying technology and tradition, the country offers valuable lessons in adaptive growth.

Watching Indonesia’s economic ascent inspires international cooperation. Developing nations witness firsthand the influential power of embracing industrial change proactively.

Global conglomerates eye Indonesia, eager to replicate its strategies in markets with untapped potentials. These collaborations pave the way for innovations beyond current technological horizons.

As Indonesia garners recognition as a trailblazer, other nations face compelling choices. Following in these footsteps could reshape their economic landscapes, paving partnerships built on shared technological visions.

Indonesia's strategic journey into welding automation exemplifies foresight and resilience. Innovations act as catalysts, propelling forward both human and technological progress.

Investments in education and infrastructure lay the groundwork for continuous development. This holistic approach weaves sustainability into the fabric of industrial growth.

Yet, these advances create expectations alongside opportunities. Industries, governments, and citizens must remain agile and innovative, ensuring sustained progress beyond immediate gains.

Indonesia’s tale offers inspiration—a story of transformation where challenges become triumphs. The horizon is vibrant and full of promise, a testament to what’s achievable when vision meets determination.

Indonesia’s welding automation journey is a beacon of pragmatic progress. The country’s resolve to merge tradition with innovation redefines what's possible in a fast-paced, ever-evolving global market.

Sharing these milestones amplifies its impact, inviting others to explore the horizon of industrial possibilities. Bookmark and share this narrative—Indonesia’s advances truly set the stage for the future of manufacturing.