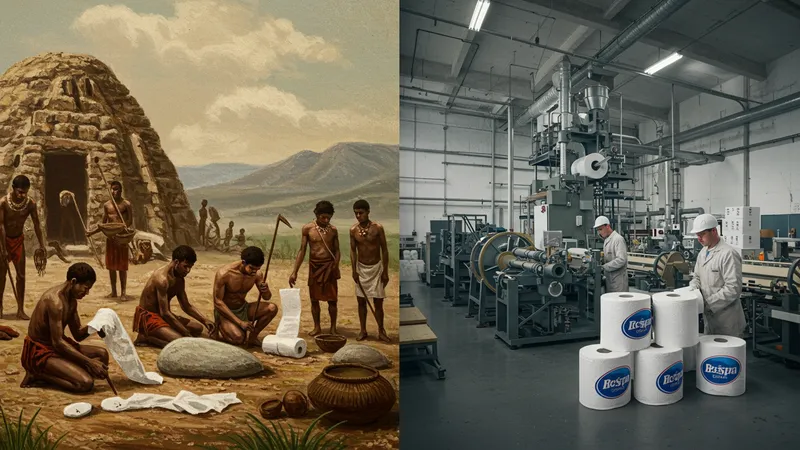

Imagine an everyday product whose evolution spans from primitive nature-based methods to today's highly engineered consumer staple. The journey of toilet paper is a fascinating reflection of technological advancements, shifting cultural norms, and continuous efforts to improve comfort and hygiene. Understanding how people transitioned from early resources to the modern manufacturing of toilet paper reveals an unexpected depth behind something so commonplace.

Long before the invention of paper as we know it, various cultures devised their own means of personal hygiene using materials sourced directly from their surroundings. Over centuries, what was once a basic practice developed into a sophisticated, large-scale industry with products designed for comfort, convenience, and sanitation. This progression is not merely about the materials used, but about innovation, marketing, and adaptability to changing lifestyles.

The earliest recorded personal hygiene practices involved natural materials, like leaves, grass, or even seashells, depending on availability and local tradition. This period, stretching across ancient civilizations, demonstrates human ability to adapt to immediate environments without the benefit of industrial products.

In the 6th century, China’s ingenuity gave rise to the first paper products meant for personal cleaning. Archaeological and literary evidence indicates wealthy households commissioned special sheets, a sign of both status and transition toward manufactured hygiene solutions. Other regions, including the Islamic world and ancient Rome, pursued alternatives aligned with their resources and beliefs.

It wasn’t until the 19th century in the West that perforated, roll-based toilet paper became commercially available. Companies like Scott Paper Company revolutionized practices by introducing individually cut sheets, then continuous rolls, evolving manufacturing processes to meet rising demand. Packaging, branding, and distribution soon followed, making toilet paper a household essential.

Contemporary manufacturing involves advanced processes to create multiple layers, enhanced softness, and even features such as recycled content and dermatological safety. Leading brands compete to offer the most luxurious or environmentally responsible options, pushing innovation in fiber sourcing and production efficiency. Understanding these stages frames toilet paper not as a mundane article, but as a dynamic product shaped by human need and invention.

As ordinary as toilet paper may appear, its journey from primitive origins to a modern manufactured good encapsulates innovation and adaptation on a global scale. The deeper details reveal even more valuable insights ahead…

The transformation from nature-based solutions to modern toilet paper owes much to the materials at each stage. Early societies relied on whatever was readily at hand. In some regions, leaves, moss, or stones were favored, while others used corn cobs or water. These selections were influenced by geography, climate, and cultural preferences, underscoring how necessity shaped the methods of the time.

The innovation of paper for hygiene was a significant leap forward. In China, the earliest iterations were made from coarse rice straw and turned into large sheets. This practice spread slowly, with each culture adapting paper’s availability and utility to suit local habits. Papyrus in Egypt and hemp-based papers in Asia marked critical steps in this ongoing evolution.

By the 19th century, the onset of industrialization allowed for the mass production of paper goods. Paper mills with mechanized pulping processes could create vast quantities of soft, rollable sheets. Perforations and convenient sizing further distinguished these modern versions from their handmade predecessors, reflecting a rising demand for ease and hygiene.

Present-day toilet paper relies on finely tuned blends of virgin and recycled pulp, often sourced from sustainable forestry initiatives. New features, such as added aloe or lotions, and improvements in ply count contribute to both tactile comfort and enhanced absorbency. These continual upgrades highlight just how far the materials and methods have progressed, setting the stage for further innovation in the years ahead.

Advancements in toilet paper manufacturing have been pivotal in shaping both quality and accessibility. Early mechanical processes focused on simple pulping and sheet formation, but soon evolved into intricate systems involving bleaching, embossing, and layering. Improvements in water management and energy efficiency have also marked recent decades, aligning production with environmental priorities.

Cutting-edge factories now employ high-speed paper machines capable of producing miles of tissue per hour. Robotics streamline packaging, while computer monitoring optimizes consistency and softness. Safety protocols and quality assurance have become integral, ensuring the end product meets global standards for hygiene and durability.

The move toward eco-friendly production has led to significant investments in both materials and machinery. Recycled content, reduced water consumption, and innovative fiber sources such as bamboo are gaining market share. Brands tout certifications from organizations emphasizing responsible sourcing and minimal environmental impact, emphasizing the link between manufacturing and sustainability.

These innovations have not only improved the consumer experience—offering stronger, softer, and more absorbent toilet paper—but have also supported a massive global supply chain. Efficiency and quality control now go hand-in-hand, illustrating the technical marvels behind everyday hygiene products.

Despite its worldwide presence, the use and manufacture of toilet paper remain deeply influenced by cultural attitudes and infrastructure. While it is standard in much of North America and Europe, many regions still favor traditional water-based methods or alternative hygiene solutions. This stems from longstanding practices, local resources, and differing views on personal cleanliness.

The arrival of modern toilet paper has in some cases represented a shift in societal norms, blending convenience with new standards of privacy and comfort. Marketing efforts by international companies have often needed to address unique cultural concerns, such as biodegradability or compatibility with sewage systems. In regions where plumbing infrastructure is less advanced, consumer preferences often diverge sharply from those found elsewhere.

In developed markets, softer multi-ply papers dominate, reflecting a demand for luxury and performance. In contrast, resource-conscious or environmentally focused communities may adopt single-ply, recycled, or even reusable options. Public spaces, hotels, and airports provide additional examples of how delivery and format adapt to meet diverse needs while maintaining hygiene standards.

This global diversity speaks to the adaptability of toilet paper as a product, as well as the ongoing evolution of manufacturing techniques to accommodate an ever-broader range of users. Understanding these dynamics adds depth to the story behind this essential good and hints at future directions as habits continue to change.

Environmental sustainability is reshaping how toilet paper is sourced, manufactured, and disposed of. With rising awareness of deforestation and resource consumption, manufacturers are increasing investments in recycled fibers, alternative raw materials such as bamboo, and closed-loop water systems. These efforts are designed to reduce the ecological impact while maintaining quality and affordability.

Certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) guide both consumers and producers toward accountable practices. Brands that prioritize responsible sourcing, reduced plastic packaging, and lower emissions are gaining traction. Education campaigns also play a role, encouraging users to make informed decisions that balance comfort with care for the environment.

Biodegradable and rapidly disintegrating toilet paper options cater to the needs of modern wastewater systems, minimizing blockages and reducing the strain on municipal infrastructure. Innovative startups continue to push boundaries, exploring zero-waste packaging, hybrid materials, and life-cycle analyses that shape future product development.

As consumer demand shifts increasingly toward sustainable solutions, the evolution of toilet paper remains far from complete. The drive for greener practices positions this everyday product as a benchmark for responsible innovation, ensuring its continued relevance in a world attentive to both comfort and conservation.