Imagine a world where warehouses operate with near-perfect efficiency, restocking, organizing and shipping items with minimal human intervention. This isn't some distant sci-fi fantasy. It's happening now, thanks to AI and automation!

Warehousing is evolving faster than ever, driven by unprecedented technological advances. As global supply chains face increasing pressure, the integration of AI and automation is not just a trend — it’s a necessity.

AI doesn't merely support logistics; it transforms them. AI systems can predict inventory needs with remarkable precision, often outperforming human planners. Such abilities aren't just innovative — they are reshaping the industry. The real kicker? Warehousing costs are plummeting, even as productivity soars. But that's not even the wildest part…

New automation technologies mean less downtime and fewer errors. Robots are becoming smarter, literally learning as they go. This can lead to an 80% efficiency increase in some operations. Imagine a future where downtime is virtually nonexistent! But wait until you hear about the unprecedented tweaks occurring behind the scenes…

What happens next shocked even the experts in supply chain management. The implications of AI and automation in warehousing could redefine how businesses operate, challenging the very foundation of logistics as we know them. Ready to dive into the depths of this transformation?

The concept of intelligent warehousing is taking flight, where automation and AI combine to anticipate market needs and optimize inventory. These systems not only track stock but also predict which items will sell out next, altering the replenishment strategy dynamically. With such foresight, businesses can significantly minimize overstocking or shortages. This approach saves time and crucially optimizes the resource allocation that has traditionally hampered growth. And that's just scratching the surface!

The efficiency of automated warehouse operations has skyrocketed. Gone are the days of manual tracking and cumbersome inventory checks. Today, sophisticated robots perform complex operations, from sorting packages to monitoring storage conditions. Imagine warehouses that autonomously adapt to shifts in demand without a hiccup. This is revolutionizing storage like never before, but there’s more to the story…

How do these intelligent systems learn? Through the fusion of machine learning and historical data analysis. Data gathered from years of operations feeds predictive models, training AI to foresee market trends and adjust operations proactively. This kind of insight paves the way for predictive warehousing, where the next big breakthrough is just an algorithm away. But wait—there’s one more twist.

Incorporating intuitive warehouse management systems means smoother, more reliable operations. Enhancements in AI algorithms mean that predictive systems are no longer just a dream for massive corporations; small businesses now have access to these cutting-edge tech advancements. The barriers of entry are crumbling, leveling the playing field. What you read next might change how you see warehousing forever.

Many argue that the initial cost of implementing AI and automation in warehousing is prohibitive. However, a closer look reveals the impressive cost benefits that these technologies bring. Companies have reported up to a 60% reduction in operational costs after adoption. The math is simple; the initial investment is overshadowed by the dramatic savings from decreased labor costs, fewer errors, and less waste. Still, this isn’t the full picture…

Automation tools have been instrumental in drastically slashing overhead costs. By optimizing energy consumption and reducing the need for extensive labor forces, businesses find themselves in the enviable position of reducing expenses while boosting profits. And it’s not just about cutting costs — the hidden efficiency of AI means a continuous increase in revenue, which traditional methods can’t match. But that’s just the beginning.

Consider real-time data analysis that AI offers. This feature fuels the power of foresight, enabling warehouses to plan for peak demand without overextending resources. The result? A drastic reduction of wasted space and idle inventory, translating into direct savings. Even if the initial expense seems steep, the balance tips heavily towards benefit as operations scale. And there's more innovation on the horizon.

The economic advantage extends to scalability. As businesses grow, AI systems adapt and evolve, eliminating the need for constant reinvestment in logistics infrastructure. Imagine running a massive warehouse with the agile efficiency of a start-up. The possibilities are boundless — and what you read next might redefine economics in warehousing entirely.

Automation doesn’t spell the end for human roles; rather, it reshapes them. As robotics take over repetitive and time-consuming tasks, human workers are repositioned into more strategic and decision-making roles. This dynamic shift fosters a richer, more collaborative workplace environment. Employees no longer expend energy on mundane activities; instead, they engage with processes that drive innovation forward. But this shift holds even deeper potential…

Integrating robotics and human expertise allows warehouses to harness the strengths of both elements. While robots offer precision and speed, human insights drive creativity and emotional intelligence — a combination ripe for innovation. Employing advanced tech alongside human ingenuity opens up avenues previously unimagined. The potential for growth is staggering, but there's still more to uncover.

A case study in the field revealed surprising productivity increases. A fully automated process, when paired with human oversight, resulted in an operational efficiency boost of over 30%. This finding challenges the myth that full automation renders human workers obsolete. Instead, it demonstrates the indomitable potential of robotic-human synergy. What comes next could redefine work as we know it.

In the evolving workplace, roles are shifting toward creativity and critical thinking. By automating the mundane, workers are liberated, unearthing initiatives that set their enterprises apart. Far from being a mere side-effect of automation, this evolution represents the pinnacle of the new industrial revolution. Prepare to glimpse a world where technology empowers rather than displaces. You won't believe what's next.

Incorporating AI into warehousing is paving the way for data-driven decision making, transforming raw data into actionable insights. With AI, businesses decipher patterns in consumer behavior, optimize supply chains, and revolutionize inventory planning. These improved capabilities allow for highly tailored strategies that directly address market demands. Picture warehouses acting as dynamic engines of commerce rather than static structures. Yet, there’s more to uncover…

Pioneering data usage means breaking away from traditional decision-making models. With real-time analytics, warehouses predict demand swings with surprising accuracy, eliminating surplus and minimizing shortages. This data revolution isn’t just smart — it’s essential for businesses aiming to stay ahead in a competitive landscape. But here's something few have considered…

This shift toward analytics not only reshapes logistics but also supports strategic growth. Detailed insights into operational weaknesses cultivate continuous improvement. By leveraging data, businesses transform potential pitfalls into opportunities for change, fostering resilience in rapidly shifting markets. Yet, the full impact of data-driven decisions is still unrecognized by many. The next big secret is just around the corner.

Decision-makers enjoy a bird's-eye view of operations, empowering them to advance strategy with precision. By integrating AI analytics with human expertise, businesses enhance their adaptive capacity, preparing for any market challenge. As the lines between prediction and action blur, warehouses evolve into thinkers and actors in the business narrative. The future holds techniques that might just redefine your understanding of business intelligence entirely.

With great technological power comes ethical responsibility. As AI and automation infiltrate more significant areas of warehousing, ethical considerations grow in tandem. Businesses must deliberate the moral implications of less human involvement in operations. The shift has generated a dialogue around job displacement and privacy concerns within digital warehouses. But beneath the surface lies a more nuanced narrative…

Ethical warehousing considers the balance between cutting-edge technology and the human factor. While automation offers numerous benefits, it should not obscure employee welfare or erode trust. It’s a delicate balance, ensuring technological advancement serves the greater good without sacrificing ethical standards. This uncharted territory demands innovative solutions. But wait, there's more to weigh in this conversation…

More automation doesn’t have to mean fewer jobs. Instead, it could signify reallocating human talent to areas of creativity and innovation. By reframing the conversation, companies can foster a culture that values both human input and technological progress. The redefinition of roles creates a more dynamic workforce prepared to adapt and thrive, maintaining ethical integrity in a rapidly evolving space. But the implications run even deeper.

Ultimately, the responsible implementation of AI in warehousing hinges on striking the right balance. Fair labor practices must accompany technological deployment, ensuring human dignity is maintained. By fostering a dialogue about ethical AI deployment, businesses not only gain public trust but also create sustainable, future-ready operations. Our next discoveries might just reshape what it means to be ethical in a tech-powered world.

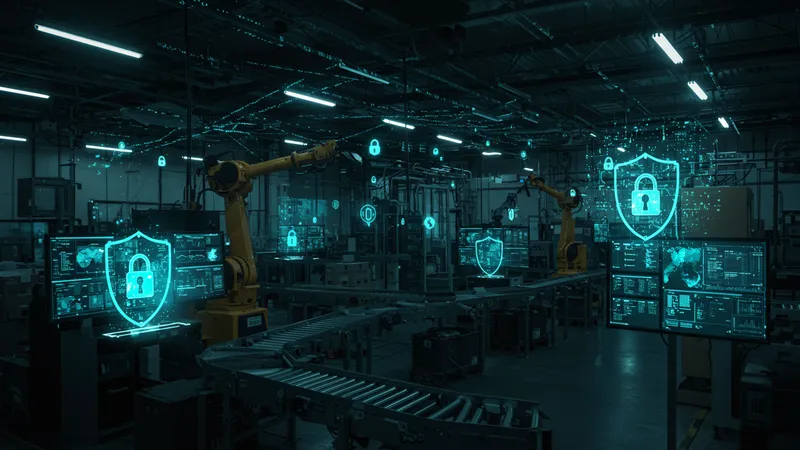

As warehouses embrace automation, cybersecurity becomes a pressing concern. With increased connectivity comes potential vulnerabilities that could compromise sensitive data. Businesses must prioritize safeguarding information from breaches, ensuring the seamless functioning of automated systems. The challenge is enormous, yet innovative solutions are reshaping this digital landscape. And there's more on this topic…

The first step in securing automated systems involves addressing inherent vulnerabilities. By employing advanced encryption protocols and conducting regular security audits, companies can prevent unauthorized access to critical infrastructure. This proactive approach establishes a robust digital defense, equipping warehouses to combat potential threats effectively. But the discussion doesn't stop here…

Ultimately, security in automation requires comprehensive strategies focusing on detection and response. Modern systems incorporate AI to identify irregular activities, triggering alerts before significant damage occurs. This level of vigilance reinforces trust in automation, enabling seamless operations with minimal disruptions. As we delve deeper, it becomes clear this is not just a technical issue but a pivotal business necessity.

The future of warehousing relies on robust security foundations. Ensuring the longevity of these systems involves constant vigilance and adaptation. Companies that harness technology responsibly will find themselves not only surviving but thriving in a competitive marketplace. With breakthroughs in artificial intelligence and security on the horizon, the stakes have never been higher for innovation in automated warehousing.

As AI evolves, so too does its potential in reshaping warehousing. Predictive warehousing, where AI anticipates trends and preempts needs, is not just a possibility—it's the imminent reality. By assessing past data, AI identifies patterns that forecast consumer behavior, empowering warehouses to respond immediately. The resulting precision maximizes efficiency and reduces waste. But the impact goes even further…

Predictive AI challenges traditional models, enabling warehouses to adapt proactively rather than reactively. This shift offers companies a strategic advantage in managing supply chains. By extending beyond basic stock management, AI insights refine logistics networks, creating a future where interruptions are rare and quickly resolved. What comes next could redefine industry standards.

The implications extend from supply chains to end consumer experiences. With increased precision, inventory availability aligns closely with demand, enhancing customer satisfaction. Retailers can better meet expectations with real-time stocking solutions that prevent delays. This alignment cultivates loyalty and strengthens customer relationships. However, not all aspects have been explored just yet…

Widespread adoption of predictive AI requires a significant cultural shift. From managing tangible resources to relying on digital intelligence, businesses must trust technology's capabilities. The potential is transformative, ushering in an era where warehousing becomes a strategic partner in delivering consumer value. As we explore further, you'll see how the future of AI in logistics may transform business relationships everywhere.

As businesses commit to sustainability, AI's role in promoting green warehousing is growing more prominent. By optimizing logistics, AI reduces carbon emissions and energy use, aligning with eco-friendly practices. AI-driven systems enable precise climate controls and energy-efficient routing, contributing to a significant ecological impact. However, there’s a deeper narrative…

Optimized warehouse operations minimize waste and enhance resource allocation. Through intelligent monitoring, AI reduces the environmental footprint, fulfilling corporate responsibility while benefiting from cost savings. These advanced systems make sustainability a viable reality for businesses seeking to balance growth with ecological stewardship. Yet, the story doesn't end here…

Greater transparency and traceability offered by AI foster accountability. Businesses gain insights into every facet of their operations, from energy usage to material sourcing, enabling responsible decision-making. Enhanced transparency strengthens trust with consumers who increasingly prioritize sustainability. But the potential for AI's impact runs wider and deeper…

The ongoing integration of AI within green practices positions businesses at the forefront of sustainable innovation. It’s a compelling shift that accelerates progress toward long-term ecological balance. Embracing these trends empowers companies to lead by example, setting new benchmarks for environmental responsibility. You won't believe how these technological advances might shift sustainable paradigms next.

AI and automation are not just affecting individual warehouses but are transforming global supply chains. By integrating these advanced technologies, businesses streamline their operations across borders, enhancing communication and coordination. This elevation reduces friction, promoting seamless international logistics. But unveiling this impact reveals even greater potential…

The adoption of AI fosters tighter integration within supply chain networks, reducing delays and predictions errors. Enhanced tracking and flexibility afford businesses the resilience to handle disruptions, positioning them advantageously in an unpredictable global market. This is reshaping the landscape, but many haven't explored its full implications…

Through advanced algorithms and data analysis, AI offers visibility into every operation, from resource procurement to retail delivery. These insights streamline production and distribution, minimizing costs and maximizing efficiency. Greater predictability stabilizes supply chains in outstanding ways, ensuring reliability no matter the external pressures. However, the ultimate potential remains on the horizon…

Automation is unlocking possibilities that defy traditional logistics boundaries. When applied on a global scale, it creates unprecedented opportunities for collaboration and innovation. As supply chains become smarter, they integrate more fluidly with global markets, ushering in an era of dynamic, borderless commerce. What you uncover next might forever alter your perspective on international trade logistics.

From the author's perspective, witnessing these changes first-hand reveals unexpected lessons. AI and automation are more than abstract concepts; they redefine daily operations, delivering tangible benefits. Observing the resilient adaptability challenges preconceived notions, demystifying technology's role in logistics. However, this is just the beginning…

The revolution of AI in warehousing offers lessons in resourcefulness and innovation. Adapting to technology's rapid advancements requires a willingness to explore uncharted territories. The unexpected flexibility of human ingenuity when paired with tech advances creates a synergy that exceeds the sum of its parts. This merger underscores ongoing adaptation. Yet, not all has been addressed…

Beyond the tangible results, the emotional impact filters throughout organizations. The shift towards automation fosters a mindset of continuous learning, questioning traditional assumptions and encouraging progressive change. It teaches resilience, emphasizing the need for leaders to be forward-thinking. A significant mindset shift continues to unfold, offering introspective insights. But there’s a final reflection to consider…

AI and automation shape not just industries but personal journeys. The compelling balance between familiar and futuristic calls for a reevaluation of one’s core beliefs and practices. By embracing change, individuals align with technological progress, ready for tomorrow's challenges. As we conclude our exploration, you've joined us on a transformative journey into warehousing’s future, highlighting the enduring spirit of innovation.

As AI and automation revolutionize warehousing, we've unveiled their profound impact across industries. From cost-effectiveness to ethical considerations, these transformations offer rich lessons for anyone willing to delve deeper. Harness this knowledge to innovate responsibly, aligning progress with integrity. And don't just keep these insights to yourself—share them with others, bookmark this exploration for future reference, and initiate conversations to drive change. The future isn't waiting, it's here.