Imagine cutting your warehouse operating costs by 30% almost overnight. That's exactly what some businesses are experiencing with the latest advancements in Warehouse Management Systems (WMS). The future of logistics is changing faster than you think.

In a world where efficiency can make or break a business, understanding the power of WMS is crucial. The stakes are higher than ever as global supply chains are strained and consumer expectations skyrocket.

WMS technology is not just about tracking inventory; it's about transforming operations. Some systems have predictive capabilities that anticipate demand and adjust stock levels proactively. Businesses report increased efficiency, but here’s the kicker – over 60% of small to medium enterprises still rely on outdated methods. But that's not even the wildest part…

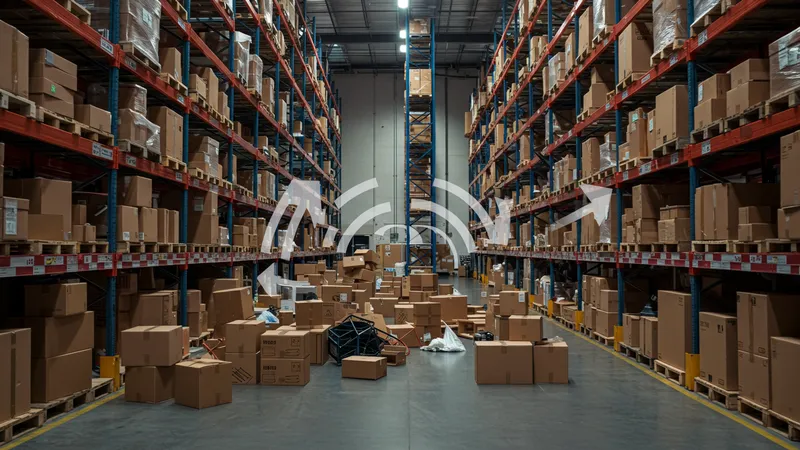

Shifting to a WMS can seem daunting, yet the real shock comes when these systems start revealing inefficiencies you didn’t know existed. Companies have discovered hidden bottlenecks and unaccounted hours. The revelations are often astounding, leading to massive overhauls in strategy. What happens next shocked even the experts…

The beauty of modern Warehouse Management Systems lies in their ability to offer real-time data. Traditionally, warehouses relied on periodic updates, sometimes delaying adjustments that could prevent inventory pile-up or shortages. But with WMS real-time capabilities, everything from stock levels to shipment schedules is at your fingertips. Imagine making data-driven decisions at a moment's notice.

This is not just theory; businesses that leverage real-time data have reported a whopping 25% reduction in lead times. The key lies in being proactive rather than reactive. But there's one more twist you might not expect: companies find that real-time data helps in making smarter workforce allocation decisions, which in turn significantly cuts labor costs. Isn't that a revelation?

Consider this fascinating insight: warehouses that implement real-time WMS see an average of 33% reduction in human errors. Mistakes were often due to outdated information. But here's what even seasoned warehousers overlook: the impact on customer satisfaction. Quick and accurate order fulfillment skyrockets customer reviews and loyalty, proving that little changes can create big ripples.

So, what’s holding companies back from using this capability to its full potential? Often, it’s the fear of technology investments. However, when weighed against the potential for reducing operational costs, it's a worthy risk. What you read next might change how you see this forever.

While the upfront cost of implementing a WMS might make some entities pause, the hidden costs of not having one are profound. For example, inventory mismanagement due to lack of a centralized system can lead to overstocking, which ties up capital and incurs storage costs. The impact of these inefficiencies can be staggering.

Warehouse mismanagement causes a ripple effect of issues, from delays causing damaged goods to dissatisfied customers and lost sales. Not addressing these hidden costs can consume profits in the long term, which brings us to a startling statistic: businesses report losing up to 20% in annual profits due to inventory inaccuracies. Have your eyes been opened yet?

Another aspect that's less spoken about is the cost of integrating legacy systems with WMS. It can be a technical nightmare, filled with hidden fees and unexpected downtime. Yet, those who endure the transition often report a return on investment within two years. Isn't that eye-opening? The transition not only streamlines logistics but also enhances integration across different departments.

On a more positive note, post-integration efficiency gains are incredible. More than just cost-cutting, it's about unlocking potential. Businesses report improved accuracy and faster processing times. Lastly, keep this curveball in mind: every penny invested can boomerang into greater profits and greater molds of efficiency. But is that all there is? Think again.

While WMS offers a technology-driven approach, human factors can present significant roadblocks. Employees accustomed to traditional systems often exhibit resistance to change, fearing that automating tasks will replace their jobs. Interestingly, studies show automation also creates new roles, often elevating employee satisfaction in the process.

Training employees to adapt to WMS is a hurdle that shouldn’t be underestimated. Over 70% of warehouses report needing comprehensive training programs to bring staff up to speed on new systems. The irony is palpable because while WMS reduces errors, improper use can introduce new problems if training isn't thorough. Isn’t it intriguing how full-circle it can come?

Consider the psychological hurdle: change management. This involves fostering a culture that is open to innovation. Leadership plays a pivotal role in this transition by actively addressing fears and communicating benefits. When employees see the reduction of mundane tasks, they often express gratitude for the shift rather than lamentation. Sometimes, changes aren’t about the tools but the mindset.

But that’s not the whole picture. Employees aren't the only ones who need convincing. Stakeholders and investors often have reservations about investments in new technology. They need reassurances about system reliability and demonstrable ROI. How do you effectively bridge this gap? The answer might surprise you—it doesn’t involve tech at all.

Artificial Intelligence in Warehouse Management Systems is not just a buzzword; it’s the new norm. AI enhances decision-making by providing predictive analytics, which massively benefits inventory management. Picture predicting sales trends months in advance—this is the new frontier for proactive inventory restocking strategies.

One unexpected twist: AI capabilities in WMS can even optimize picking routes and warehouse layouts for maximum efficiency. Imagine reducing walking time by 10 minutes per hour for workers. Doesn’t that transform how you visualize warehouse floors? These changes, though small in daily execution, compound to significant annual time savings.

But the wonders of AI don’t stop there. Machine learning models within WMS can learn from past mistakes, identifying and addressing recurring issues long before they escalate. The systems continuously adapt, meaning problems become learning opportunities, not points of failure. Are you beginning to see the pattern here?

And here's something to consider: AI is making significant strides in reducing energy consumption, making operations more sustainable. By optimizing heating, cooling, and lighting according to activity, warehouses can reduce utility costs significantly. These are also eco-friendly measures that appeal to today’s eco-conscious stakeholders. Who knew AI could be this impactful?

While technology is a driving force in warehousing, preserving the human element is essential. Employees often fear becoming redundant; however, the focus should be on enabling them to perform intelligent work. Technology should complement, not compete, with the workforce.

Surprisingly, Warehouse Management Systems create opportunities for employees to upskill. With the implementation of new systems, training programs often lead to certifications that employees can leverage for career advancement. It’s a fulfilling process where both employees and companies gain a competitive edge. Isn’t this more than just a technological advancement?

Love it or hate it, human intuition still plays a vital role in decision-making. WMS can provide data, but interpreting and executing based on that data often requires a human touch. This revelation debunks the myth that technology entirely eradicates the need for human presence in the warehouse. Isn't that comforting?

Now, consider how synergy between tech and human effort leads to customer satisfaction. Employees empowered by tech can offer quicker solutions to client queries. Anticipating client needs and addressing them efficiently creates brand loyalty. So, every byte of data processed translates eventually to human approval. Now, what might the future hold for this human-tech partnership?

The integration of the Internet of Things (IoT) with Warehouse Management Systems marks a new era. IoT devices offer unprecedented connectivity and communication between various warehouse components. With the ability to track and monitor assets in real-time, efficiency and transparency are ensured. Imagine never losing an asset again. It’s revolutionary.

IoT sensors provide critical data about temperature, humidity, and location, ensuring optimal conditions for sensitive goods. This level of detail wasn’t possible before, and it supports compliance with industry regulations. Isn't it exciting to see technology provide peace of mind?

A practical advantage of IoT is reducing waste. Companies report up to 40% waste reduction due to better monitoring and management of perishable goods. By tackling spoilage before it happens, IoT presents a brilliant intersection of technology and sustainability. Isn’t it fascinating how small changes can redefine operations?

Looking forward, IoT’s potential seems boundless. It could permit automatic stock reordering when sensors detect low inventory levels, freeing up human resources for more critical tasks. But even more intriguing is the possibility of creating entirely automated facilities. Could this mean the end of human involvement? The implications are massive.

The recent global crises have tested supply chains worldwide like never before. In such scenarios, having an effective Warehouse Management System is crucial. With sudden demand changes, WMS enables swift adjustments to operations, ensuring that supply meets demand.

Here's a shocking stat: During crises, companies with WMS reported a 50% faster recovery in their supply chain operations than those without. This demonstrates the significance of having real-time analytics and flexible operations. It’s a game-changer in unpredictability. Isn't it compelling?

Moreover, WMS can maintain continuity during staffing shortages through automation. The systems can retain operational efficiency despite reduced manpower, a vital factor during global crises. It’s a solid strategy for risk management that many companies are now realizing. Could this shape future operations?

Looking ahead, it’s clear that resilience needs to be built into the system design itself. With businesses globally recognizing this need, a WMS's role becomes indispensable. The pursuit of adaptability is undeniable, attracting companies to invest in WMS. As the world navigates these turbulent times, will WMS become a staple of crisis management strategy?

Scaling a business is thrilling yet challenging, particularly regarding warehouse operations. Here is where a flexible, scalable Warehouse Management System shines. WMS allows small to medium enterprises to expand without the overwhelming capital investment typically required for a warehouse expansion.

Flexibility in scaling operations means adding or reducing facilities and workforce as needed with minimal disruption. This adaptability accommodates growth without significant restructuring. Isn’t it comforting to know that systems exist to support expansion as fluidly as possible?

Consider the savings: companies using WMS during growth spurts report minimizing additional costs by an average of 15%. These systems allow seamless handling of increased operations through optimized processes without requiring significant investments in new infrastructure.

A further unexpected advantage is strategic planning. Advanced WMS provide predictive analytics that guides growth strategies by enlightening businesses on potential pain points before they arise. Isn’t it a breath of fresh air that growth can be framed with foresight rather than as a frantic scramble for space and resources?

For small businesses, implementing Warehouse Management Systems might seem like a daunting leap. However, ignoring WMS can mean missing out on exceptional operational advantages. The good news is that there are tailored, cost-effective solutions available for smaller operations.

A WMS designed for small businesses simplifies inventory management and offers a competitive edge. These systems often come with a less intimidating price tag while providing essential functions like real-time tracking and inventory analysis. It’s a revelation that such powerful tools are within reach of smaller players.

An unexpected benefit is improved customer service. Small businesses using WMS experience faster fulfillment, leading to better customer satisfaction and repeat business. It elevates them to effectively compete with larger enterprises. This is what many call leveling the playing field.

Ultimately, WMS for small businesses offers a strategic advantage without the burden of massive costs. The systems streamline processes like order fulfillment and inventory restocking. Investing in WMS means stepping confidently into a future where scale and efficiency are no longer exclusive to big businesses. But this is only the beginning. Let’s explore what's around the corner for small businesses.

In today’s eco-conscious world, businesses are striving to implement sustainable practices, and Warehouse Management Systems can be key players in this transformation. WMS facilitates reducing carbon footprints through better resource management and energy-saving practices.

One fascinating aspect is how companies utilizing WMS have reduced energy costs by 20% simply by optimizing inventory cycles and cutting down wastage. This isn’t just good for the bottom line; it’s a strong commitment to sustainability. Isn’t it compelling to realize how green WMS can be?

In addition to reducing energy costs, smart WMS promotes efficient use of space, minimizing the need for additional warehouses and thereby preserving land and resources. Such measures amplify the importance of environmentally conscious warehousing solutions. It’s revolutionary.

Moreover, companies are increasingly focusing on reducing their ecological impact while still maximizing efficiency. By adopting WMS, businesses not only witness immediate benefits but also contribute to a broader global initiative. The push towards sustainability could redefine how warehouses operate, setting an entirely new standard.

Adopting a Warehouse Management System isn’t a decision made lightly. It involves understanding the needs of your business and the capabilities of the system. Before making the switch, companies should consider compatibility with existing systems, the complexity of integration, and long-term scalability.

It’s crucial to evaluate the cost-effectiveness of a WMS versus the problems it aims to solve. Costs can vary widely, and a solution should be tailored to meet specific business goals. Sometimes, it requires revisiting business strategies to align with the capabilities offered by WMS. Isn’t it intriguing to shift strategy through these lenses?

Furthermore, engaging stakeholders from the start facilitates smoother transitions and clarifies the need and value of the investment. Implementing WMS is a commitment that involves budget planning, process tweaks, and possibly, reevaluating company objectives.

On the brighter side, these challenges come with significant rewards: streamlined operations, cost reductions, and a boost in efficiency. Doesn’t it seem worthwhile to trade off short-term challenges for long-term prosperity? The decision-making process demands careful consideration and strategic insight for the benefits to be fully realized.

As we've journeyed through the labyrinth of Warehouse Management Systems, one thing is clear: innovation is consistently reshaping how warehouses function. From embracing AI and IoT to the emphasis on human elements and eco-friendly solutions, WMS prove indispensable in the quest for efficiency.

For those engaged in warehousing, whether you're at a multibillion-dollar titan or a burgeoning small business, WMS offers tools that equalize opportunity and power. Share this with colleagues, bookmark it as you weigh your options, or dive deeper to see how a tailored system can redefine your operations. The future awaits you're part of its unveiling.